Die Casting

ForceBeyond provides superior quality custom die casting parts and components for a wide range of industries including automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others.

Our die casting machines range from 180 up to 2,000 metric tons, we can produce die casting parts from a few grams to more than 100 pounds with superior quality ready for assembly. For die casting parts with requirements of esthetical, functional, or protective coatings, we also offer a broad range of surface finishing including powder coating, e-coating, shot blasting, chrome plating, and bright finish.

What Is Die Casting?

Die casting is a metal casting process characterized by pressuring molten metal into the mold cavity. The mold cavity is created using two hardened tool steel molds that are machined during processing and work similarly to injection molds. Most die-castings are made from non-ferrous metals, especially zinc, copper, aluminum, magnesium, lead, tin and tin-based alloys. Depending on the type of metal being cast, thermal or cold machines are used.

How are Die Castings Made?

Steel dies capable of producing tens of thousands of castings in quick succession must be made in at least two sections to allow the castings to be removed. These parts are firmly mounted in the machine and are arranged so that one is stationary (fixed die half) and the other one is movable (syringe half-mold). To begin the casting cycle, the two mold halves are clamped together by a die-casting machine. Molten metal is injected into the mold cavity and rapidly solidified. The mold half is opened and the casting is ejected. Die-casting molds can be simple or complicated, with moveable slides, cores or other parts, depending on the complexity of the casting.

To date, the complete cycle of die casting has been the fastest cycle to produce precision nonferrous metal parts. This is in stark contrast to sand casting, which requires new sand molds for each casting. Although the permanent mold process uses iron or steel molds instead of sand, it is much slower and less precise than die castings.

Watch the video of our die casting facility to learn how die castings such as aluminum die castings, zinc die castings are made. Video also available on youtube.com.

Advantages of Die Casting

- Simple or complex shapes

- Thin wall thickness

- Light weight

- High rates of production

- Corrosion resistance

- Monolithic – combine multiple functions in one

- Efficient and economical alternative to other processes

- Thin wall thickness – up to 0.040 inch for small castings

- Light weight – light alloys are used

- Corrosion resistance – surfaces are smoother than other casting types

Die Casting Material Information

| Material | Tensile Strength (Mpa) | Thermal Conductivity (W/mK) | Features |

|---|---|---|---|

| Aluminum A380 | 325 | 96 |

|

| Aluminum A360 | 317 | 113 |

|

| Aluminum 413 | 295 | 121 |

|

| Aluminum 383 | 310 | 96 |

|

| Aluminum B390 | 317 | 134 |

|

| Aluminum A413 | 290 | 121 |

|

| ZAMAK 2 | 359 | 105 |

|

| ZAMAK 3 | 283 | 113 |

|

| ZAMAK 5 | 328 | 109 |

|

| ZA 8 | 374 | 115 |

|

Secondary Operations of Die Casting We Offer

- High precision CNC machining, milling, drilling, tapping, e-coating, anodizing

- Painting, sanding, shot blasting, powder coating, chrome plating

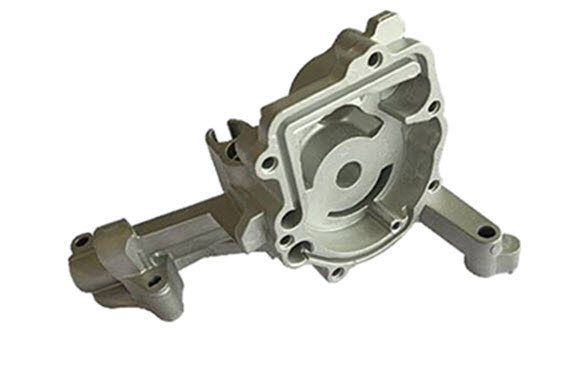

Aluminum Die Casting Parts and Zinc Die Casting Parts

Sources

- American Foundry Society. “Metal Casting”

- Wikipedia. “Investment Casting“, “Sand Casting“

- efunda. “Sand Casting“

- The Investment Casting Institute. “What is Investment Casting?“

- The Library of Manufacturing. “Investment Casting“

- Forging Industry Association “Forging Industry“

Our Internal Resources for Die Casting, Investment casting, Forging and Sand Casting

- Die Casting

- Aluminum Die Casting

- Zinc Die Casting

- A356 Aluminum Casting with T6 Heat Treatment

- Magnesium Die Casting

- Investment Casting

- Stainless Steel Casting

- Duplex Stainless Steel Casting

- Super Duplex Stainless Steel Casting

- Titanium Casting

- Carbon & Low Alloy Casting

- Forging

- Cold Forging

- Hot Forging

- ECO BRASS C69300 Brass Forging

- Sand Casting (Aluminum Sand Casting, Ductile Iron Sand Casting, Gray Iron Sand Casting)

- Specialty Fittings and Fasteners

- Precision CNC Machining and Secondary Operations